A robot battery is the lifeblood of any robotic system. Without a reliable power source, robots, no matter how advanced their design or capabilities, are rendered immobile and ineffective. Just as the human body needs a constant supply of energy to function, robots rely on batteries to carry out their tasks, whether it’s in industrial manufacturing, healthcare assistance, or space exploration.

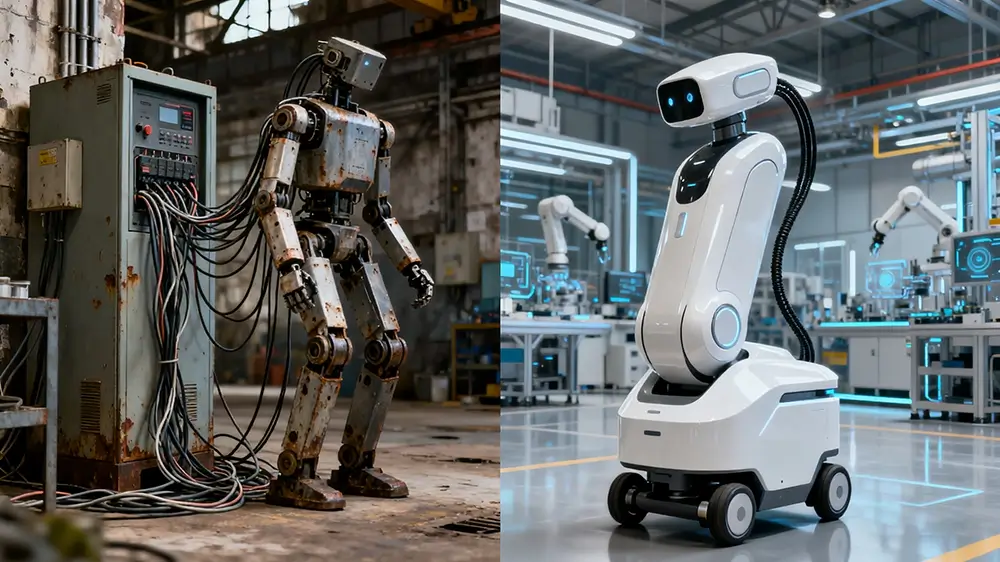

In the early days of robotics, the limitations of robot batteries severely restricted the development of these mechanical marvels. Early robots were often tethered to power sources, which limited their mobility and flexibility. However, as battery technology has advanced, so too has the potential of robotics. Today, we see robots in a wide range of applications, from autonomous vacuum cleaners in our homes to complex surgical robots in operating rooms, all made possible by the continuous improvement of robot batteries.

Current Landscape of Robot Batteries

Types of Batteries in Use

Currently, several types of batteries power robots, each with its own set of advantages and disadvantages. Lithium – ion batteries are a popular choice due to their high energy density. This means they can store a large amount of energy in a relatively small and lightweight package, making them ideal for robots that require portability and long – lasting power without adding excessive weight. For example, in many service robots like the Roomba vacuum cleaners, lithium – ion batteries allow for extended cleaning sessions in a compact device. They also have a low self – discharge rate, which means they can hold their charge for a long time when not in use.

However, lithium – ion batteries do have drawbacks. They can be expensive to produce, which increases the overall cost of the robot. Additionally, they require careful management to prevent over – charging and over – discharging, as these conditions can reduce their lifespan and even pose safety risks, such as the potential for overheating or catching fire in extreme cases.

Lead – acid batteries are another option, especially in some industrial and large – scale applications. They are relatively cheap and have a high discharge rate, which means they can provide a large amount of power quickly. This makes them suitable for heavy – duty robots that need to perform tasks requiring a lot of energy in a short time, like some industrial forklift robots. Moreover, lead – acid batteries are well – understood and have a long – established recycling infrastructure.

Nevertheless, they are much heavier than lithium – ion batteries for the same amount of energy storage, which can limit the mobility of the robot. They also have a relatively short lifespan and a high self – discharge rate, requiring more frequent charging and maintenance.

Capacity and Endurance Challenges

One of the major challenges in robot batteries is their capacity. Despite advancements, the energy density of current batteries is still far from sufficient for many demanding applications. For instance, in long – distance delivery drones, the battery capacity often limits the payload they can carry and the distance they can travel. A drone may need to be large and heavy just to accommodate a battery that can power it for a reasonable delivery range, which in turn reduces its efficiency and cost – effectiveness.

Endurance, closely related to capacity, is also a significant hurdle. Robots used in continuous operation scenarios, such as 24/7 surveillance robots or industrial robots on long – shift production lines, struggle to maintain operation without frequent recharging. This not only disrupts the workflow but also increases the overall cost of operation due to the need for additional charging equipment and downtime management.

The limitations in battery capacity and endurance also restrict the development of more complex and capable robots. For example, robots designed for deep – space exploration or long – term underwater missions face extreme challenges. In space, solar power can be an option, but it is not always available, and the batteries need to store enough energy to power the robot during periods of darkness or when the solar panels are not functioning optimally. Underwater, the lack of easy access to charging sources means that a robot’s mission duration is severely limited by its battery life.

Key Factors in Robot Battery Development

Technological Advancements

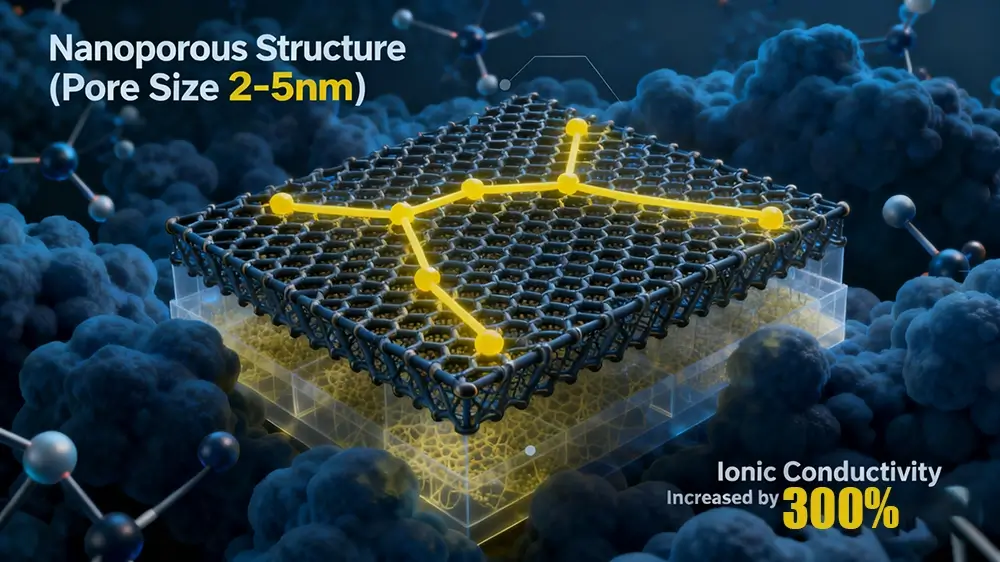

The development of robot batteries is propelled by significant technological advancements. In materials science, researchers are constantly exploring new materials to improve battery performance. For example, the use of nanomaterials has shown great promise. Nanostructured materials can enhance the conductivity of electrodes in batteries. This allows for faster charging and discharging rates, which is crucial for robots that need to quickly respond to tasks or recharge during short breaks.

Another area of progress is in the development of new electrolyte materials. Solid – state electrolytes are being studied as a potential alternative to the liquid electrolytes commonly used in lithium – ion batteries. Solid – state electrolytes can potentially offer higher energy density, improved safety, and longer lifespan. They are less likely to leak or catch fire, which is a major advantage for robots operating in various environments.

Battery management systems (BMS) are also undergoing optimization. A BMS is responsible for monitoring and controlling the charging and discharging processes of a battery. New algorithms and sensors are being developed to make BMS more accurate and efficient. These improvements can prevent over – charging and over – discharging, thereby extending the battery’s lifespan and ensuring its stable operation. For instance, advanced BMS can predict the remaining battery life more precisely, enabling robots to plan their tasks better and avoid unexpected shutdowns.

Cost – Benefit Considerations

Cost plays a pivotal role in the development of robot batteries. High – cost batteries can significantly increase the overall price of robots, making them less accessible to a wide range of users and industries. In industrial applications, where large numbers of robots are often deployed, the cost of batteries can be a major factor in the decision – making process. For example, in a large – scale automotive manufacturing plant with hundreds of robots, even a small reduction in the cost of each robot’s battery can lead to substantial savings over time.

To reduce costs without sacrificing performance, manufacturers are exploring economies of scale. By increasing production volume, the cost per unit of battery production can be lowered. Additionally, research into more cost – effective manufacturing processes is ongoing. Simplifying the production steps or using more abundant raw materials can help bring down the cost. However, this must be balanced with the need to maintain or improve battery performance.

Another cost – benefit aspect is the total cost of ownership. While a more expensive battery may have a higher upfront cost, it could offer longer lifespan, better performance, and lower maintenance requirements. For example, a high – quality lithium – ion battery might cost more initially than a cheaper lead – acid battery, but it could operate for a longer time without frequent replacements or maintenance, ultimately saving costs in the long run. Thus, when evaluating robot batteries, both the initial cost and the long – term cost – effectiveness need to be carefully considered.

Impact of Robot Batteries on the Future of Robotics

Expanding Application Horizons

The development of robot batteries is opening up new frontiers for robotics applications. In the medical field, for example, the improvement in battery technology has enabled the creation of more advanced surgical robots. These robots can perform minimally invasive surgeries with high precision. Their ability to operate for extended periods without frequent recharging is crucial, as surgeries can sometimes last for hours. With better – performing batteries, these surgical robots can be more mobile within the operating room, allowing surgeons to access different areas of the patient’s body more easily.

In search and rescue operations, robots powered by advanced batteries are making a significant impact. These robots can be deployed in dangerous environments such as collapsed buildings after earthquakes or in the aftermath of natural disasters. They can navigate through debris, search for survivors, and transmit real – time data back to the rescue teams. Long – lasting and high – capacity batteries are essential for these robots to carry out their missions effectively, as they may need to operate for days in harsh conditions where recharging is not immediately available.

Space exploration is another area where robot batteries are expanding application horizons. Robots like the Mars rovers are designed to explore the Martian surface for long periods. The batteries on these rovers need to store enough energy to power all their functions, including movement, data collection, and communication with Earth. As battery technology improves, future space robots could be sent on even more ambitious missions, such as exploring the outer planets or their moons, where the challenges of long – distance travel and limited power sources are even greater.

Shaping the Future of Automation

Robot batteries play a fundamental role in shaping the future of automation. In industrial settings, the use of robots is becoming more widespread, and batteries are a key factor in this growth. For instance, in automotive manufacturing plants, robots are used for tasks such as welding, painting, and assembly. High – performance batteries allow these robots to operate continuously on the production line, increasing productivity and reducing the need for human intervention. With longer – lasting batteries, the robots can work for multiple shifts without significant downtime for recharging, leading to higher production volumes and improved quality control.

In the logistics and warehousing industries, automated guided vehicles (AGVs) and robotic arms are revolutionizing the way goods are stored, retrieved, and transported. These robots rely on batteries to move around the warehouse, lift heavy items, and sort packages. As battery technology advances, these AGVs can cover larger areas of the warehouse, carry heavier loads, and operate more efficiently. This not only speeds up the logistics process but also reduces labor costs and human errors.

The future of smart cities also hinges on the development of robot batteries. Robots could be used for various urban services, such as street cleaning, traffic monitoring, and infrastructure inspection. Batteries with high energy density and fast – charging capabilities would enable these robots to perform their tasks efficiently throughout the city. For example, a street – cleaning robot could operate continuously during the night, cleaning the streets without disturbing traffic, and then quickly recharge during the day to be ready for the next operation. Overall, the continuous improvement of robot batteries is driving the automation revolution across multiple industries, making our lives more convenient, efficient, and productive.

Latest Trends in Robot Battery Technology

Emerging Battery Technologies

The field of robot battery technology is witnessing the emergence of several promising technologies that could potentially revolutionize the capabilities of robots. Solid – state batteries are at the forefront of these emerging technologies. Unlike traditional lithium – ion batteries that use liquid electrolytes, solid – state batteries employ solid electrolytes. This fundamental difference offers several advantages.

Firstly, they have a higher energy density potential. This means that for the same size and weight, solid – state batteries can store more energy, which is a game – changer for robots. For example, in small – sized inspection robots that need to be highly mobile while carrying out long – term monitoring tasks in industrial facilities, the high energy density of solid – state batteries could enable them to operate for much longer periods without frequent recharging.

Secondly, solid – state batteries are safer. The absence of liquid electrolytes reduces the risk of leakage and combustion, making them suitable for use in robots operating in hazardous environments, such as those in chemical plants or near flammable materials.

Another emerging technology is the hydrogen fuel cell. Hydrogen fuel cells generate electricity through an electrochemical reaction between hydrogen and oxygen, with water being the only by – product. They offer high power output and long – term energy supply. In large – scale industrial robots or robots used for heavy – duty tasks like construction robots, hydrogen fuel cells could provide the necessary power to operate continuously for extended hours. Additionally, in some applications where zero – emission operation is crucial, such as in environmental monitoring robots in sensitive ecosystems, hydrogen fuel cells are an ideal choice due to their clean – energy nature.

Integration with AI and IoT

The integration of robot batteries with artificial intelligence (AI) and the Internet of Things (IoT) is a significant trend that is reshaping the capabilities of robots. AI algorithms can optimize the power consumption of robots in real – time. For example, in autonomous delivery robots, AI can analyze the route, the weight of the payload, and the surrounding environment data to adjust the robot’s movement speed and power usage. If the robot detects a downhill section on its route, AI can reduce the power output of the motors, conserving battery energy.

Moreover, AI can predict the remaining battery life more accurately. By analyzing historical data on battery usage, the robot’s operating conditions, and the performance of the battery over time, AI algorithms can provide more precise estimates of how long the battery will last. This allows robots to plan their tasks better, for instance, by returning to a charging station in advance to avoid running out of power during an important mission.

In the context of IoT, robots can communicate with other devices and systems to manage their battery resources more effectively. For example, in a smart factory, robots can receive information about the availability of charging stations from the factory’s IoT network. They can then coordinate with each other to ensure that they charge at the most convenient times, reducing the overall energy consumption of the factory’s robotic fleet.

Additionally, IoT – enabled robots can send real – time data about their battery status to a central control system. This data can be used to schedule maintenance, order replacement batteries in a timely manner, and optimize the overall operation of the robots within the system. Overall, the integration of robot batteries with AI and IoT is enhancing the efficiency, reliability, and intelligence of robots, opening up new possibilities for their applications in various industries.

Conclusion

In conclusion, robot batteries are at the heart of the robotics revolution. From the early – stage limitations that hindered robot mobility to the current diverse range of battery options powering robots across various industries, the progress has been remarkable.

Currently, lithium – ion and lead – acid batteries are the mainstays in the robot battery market, each with its own set of strengths and weaknesses. Capacity and endurance challenges remain significant barriers, but ongoing technological advancements and cost – benefit considerations are driving the development of better – performing and more affordable robot batteries.

The future of robotics is closely intertwined with the development of robot batteries. Emerging battery technologies like solid – state batteries and hydrogen fuel cells hold great promise, with the potential to overcome current limitations and enable more advanced and capable robots. The integration of robot batteries with AI and IoT is also set to revolutionize the way robots operate, making them more intelligent, efficient, and adaptable.

As robot batteries continue to evolve, they will not only expand the application horizons of robotics in fields such as healthcare, search and rescue, and space exploration but also play a crucial role in shaping the future of automation across industries. In the coming years, we can expect to see even more innovative and powerful robot batteries that will unlock new possibilities for the world of robotics, bringing us closer to a future where robots are an integral part of our daily lives and industrial processes.