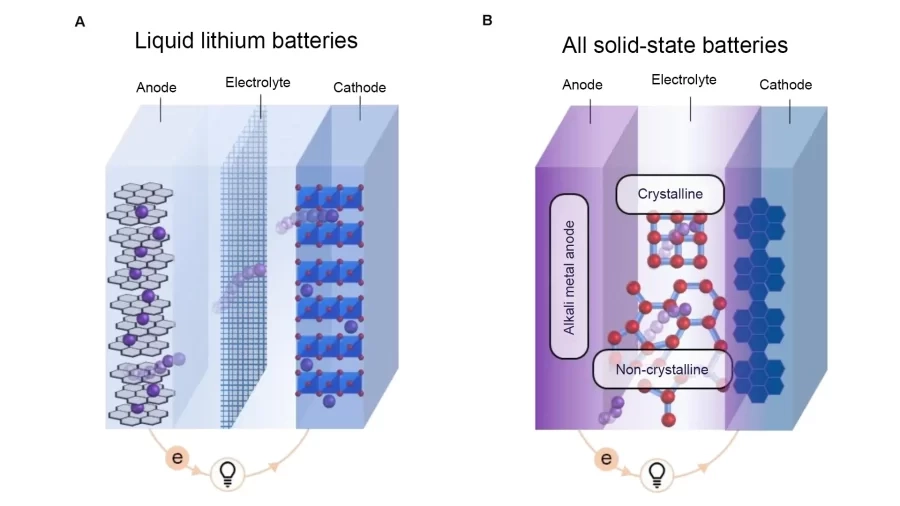

All-Solid-State Battery is the hottest topic in the 2026 battery industry worldwide. It breaks long-standing bottlenecks of liquid lithium batteries and ushers in a new era of power tech. Netizens flood social platforms to discuss its ultra-long range, fast charging and unbeatable safety. 2026 marks its shift from concept to real-world testing and small-scale mass production.

All-Solid-State Battery: 2026’s Critical Policy Milestones

China’s first national standard for Solid-State Battery launches in July 2026. The standard defines pure solid-state cores and sets strict safety indicators for the industry. It requires over 2 hours of thermal runaway protection and no fire in needle tests.

This policy ends the chaos of “fake solid-state” products on the market. It unifies battery packaging specs for car companies and battery makers. Enterprises now have clear R&D and production directions for Solid-State Battery.

MIIT lists Solid-State Battery as a core industrial upgrading technology in 2026. It sets a clear timeline: small-batch loading in 2027 and large-scale popularization in 2030. Policy support speeds up the industrialization of Solid-State Battery.

Solid-State Battery: 2026’s Groundbreaking Technical Leaps

All-Solid-State Battery achieves a huge breakthrough in energy density in 2026. Some enterprises reach 600Wh/kg for single cells, doubling liquid battery levels. Equipped models hit a maximum cruising range of 1120 kilometers.

Fast charging technology of Solid-State Battery surprises the market this year. 20C super fast charging lets cars add 500km range in just 10 minutes. It completely solves the charging anxiety of new energy vehicle users.

Low-temperature performance of Solid-State Battery gets optimized drastically. -20℃ low-temperature range attenuation is controlled within 10%. Even at -40℃, supporting models still have over 600km of range.

Cycle life of high-end All-Solid-State Battery exceeds 3500 times in 2026. Calculated by 20,000km annual driving, it can be used for more than 10 years without replacement. This cuts long-term use costs for consumers.

All-Solid-State Battery core cells and pilot production line, the core of 2026’s battery industry technological revolution.

All-Solid-State Battery: From Lab to Mass Production in 2026

Battery giants accelerate the layout of All-Solid-State Battery production lines. Gotion High-tech launches a 0.2GWh pilot line with a 90% yield rate. Its core equipment localization rate reaches 100% for cost control.

GAC Group completes the commissioning of Solid-State Battery pilot production lines. It has the capacity to produce vehicle-grade batteries over 60Ah. The company plans small-batch loading verification in 2026.

The industrial chain of Solid-State Battery is gradually improved in 2026. Sulfide electrolyte material conductivity breaks the industry high level. High-precision coating equipment realizes domestic breakthroughs.

Upstream material enterprises expand production for Solid-State Battery. Lithium manganese iron phosphate cathode materials reach ten-thousand-ton capacity. This ensures the supply chain safety of mass production.

Why All-Solid-State Battery Dominates 2026 Industry Discussions

All-Solid-State Battery perfectly solves the pain points of liquid lithium batteries. It eliminates thermal runaway risks and fire hidden dangers in use. Safety becomes its biggest advantage in public discussions.

It drives the recovery of the entire lithium battery industry in 2026. The industry ends the two-year destocking stage and enters the active stock replenishment period. Supply and demand tight balance pushes the price of battery materials up.

Netizens focus on the application scenarios of Solid-State Battery. Besides new energy vehicles, it applies to humanoid robots and energy storage. It brings longer runtime for high-power intelligent equipment.

Global competition makes Solid-State Battery a hot topic. Chinese enterprises take the lead in core technology and industrial chain. Japan and South Korea’s enterprises accelerate R&D to catch up.

All-Solid-State Battery: The Future Beyond 2026

Cost reduction is the core direction of All-Solid-State Battery in the next few years. Mass production will drive the cost down to match liquid lithium batteries. It will penetrate from high-end models to mass consumer markets.

Technological iteration of All-Solid-State Battery will not stop. Enterprises will focus on improving electrolyte conductivity and process stability. Higher energy density and faster charging will be achieved.

All-Solid-State Battery will drive the upgrading of the new energy industry chain. It will boost the development of super fast charging piles and battery recycling. A more complete new energy ecosystem will form.

The global market share of Chinese All-Solid-State Battery will expand rapidly. Complete industrial chain support and policy guidance form core competitiveness. It will provide Chinese solutions for global energy transformation.

Battewill: Powering the Era of All-Solid-State Battery

Battewill focuses on R&D and production of various lithium batteries, including All-Solid-State Battery for 2026’s market demand. Its All-Solid-State Battery cells achieve 350Wh/kg energy density and pass strict safety tests. Battewill’s products support low-temperature resistance and fast charging, adapting to new energy vehicles and intelligent equipment. The company accelerates the layout of pilot production lines, matching the industry’s small-batch loading plan in 2026. Battewill’s reliable lithium battery solutions will accompany the industrialization of All-Solid-State Battery and empower the development of the global new energy industry.