Let’s talk about warehouse robots battery.

In today’s fast-paced world of e-commerce and industrial supply chains, warehouse robots have become essential for boosting efficiency, reducing labor costs, and improving order accuracy. These autonomous machines, whether designed for picking, transporting, or stacking goods, rely heavily on one critical component: the warehouse robots battery. The performance, safety, and longevity of warehouse robot battery directly impact the overall productivity of automated warehouse operations.

Why Batteries Matter in Warehouse Robots

Unlike traditional machinery powered by wired connections or fossil fuels, warehouse robots demand compact, rechargeable, and energy-dense power sources. A reliable battery ensures continuous operation during peak demand, reduces downtime, and lowers maintenance costs. In many cases, battery technology determines the flexibility and scalability of an entire automated warehouse system.

Key warehouse robots Battery Requirements

- High Energy Density

Batteries must deliver enough power to run motors, sensors, and onboard computing systems for long shifts without frequent recharging. - Fast Charging and Swapping

In high-volume warehouses, downtime is costly. Robots need batteries that can charge quickly or be swapped seamlessly to maintain 24/7 operations. - Long Cycle Life

A durable battery with thousands of charge-discharge cycles minimizes replacement costs and enhances return on investment. - Safety and Stability

Given the close interaction between humans and robots, battery safety—thermal stability, overcharge protection, and resistance to short circuits—is essential. - Smart Battery Management Systems (BMS)

Advanced BMS technology monitors battery health, temperature, and remaining charge, ensuring efficient power usage and predictive maintenance.

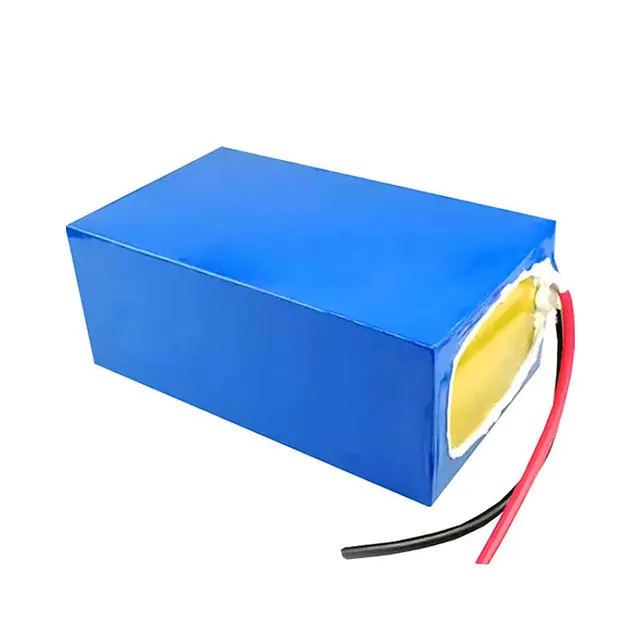

Common Battery Technologies for Warehouse Robots

- Lithium-Ion Batteries (Li-ion):

The most widely used option today, offering high energy density, fast charging, and good cycle life. - Lithium Iron Phosphate (LiFePO4):

Known for stability and safety, these batteries are favored in environments requiring consistent performance and long service life. - Nickel-Metal Hydride (NiMH):

Less common now but still used in smaller or cost-sensitive applications where moderate performance is acceptable. - Solid-State Batteries (Emerging):

An upcoming technology promising even higher safety, faster charging, and extended lifespan.

The Impact on Smart Warehousing

Efficient battery solutions enable continuous operation of fleets of robots, supporting real-time order fulfillment and lean inventory management. As businesses adopt AI-driven logistics, demand for high-performance batteries will continue to grow, pushing innovation in energy storage and charging infrastructure.

Looking Ahead

The future of warehouse robots battery lies in intelligent energy ecosystems—wireless charging stations, AI-powered battery monitoring, and recyclable materials for sustainable operations. As automation becomes the backbone of global logistics, robust battery technology will remain the driving force behind smarter, safer, and more efficient warehouses.